Recommendations for Installing Carbon Brushes on Commutators and Slip Rings

Carbon brushes play a critical role in maintaining efficient electrical contact between a commutator or slip ring and the external circuit. Improper installation can lead to reduced performance, increased wear, or even serious equipment failures. To ensure optimal performance and long service life, the following best practices should be followed.

1. General Installation Guidelines

- Do not mix different grades: Never use carbon brushes of different grades in the same machine, as this can cause uneven wear, sparking, and operational instability.

- Remove existing film layers: Before changing to a new brush grade, thoroughly clean off any existing film from the commutator or slip ring surface.

- Check brush-holder fit: Ensure brushes slide smoothly in their holders without excessive clearance. Poor fit can cause vibration, uneven wear, or overheating.

- Verify orientation: Install brushes in the correct direction. This is especially important for brushes with beveled surfaces or split brushes with metal plates.

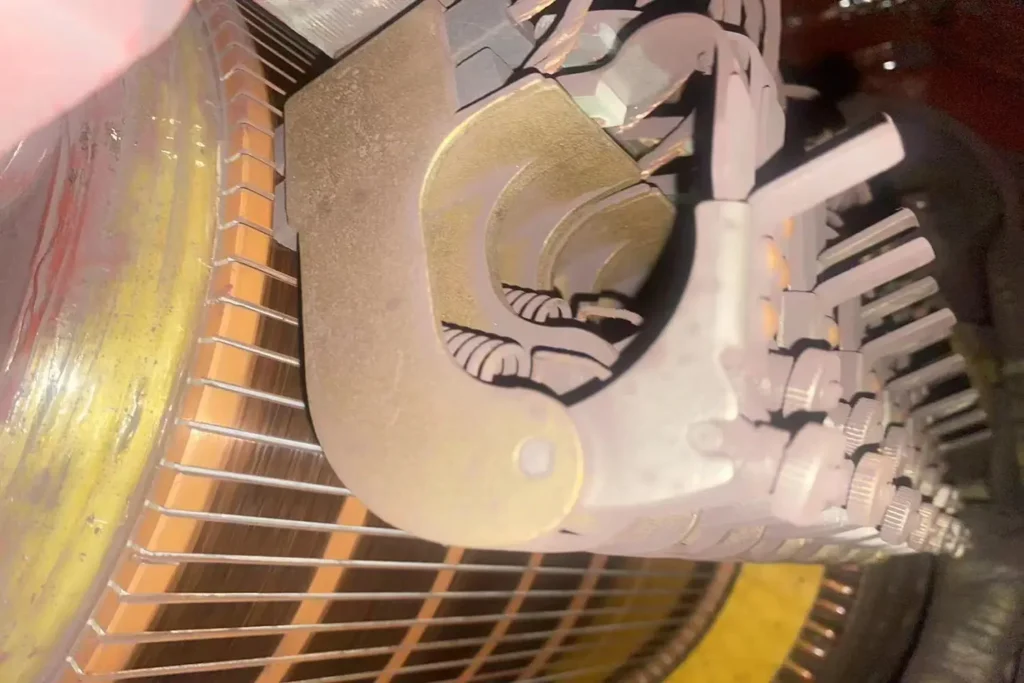

2. Seating the Carbon Brushes

For proper electrical performance, the carbon brush contact surface must precisely match the curvature of the commutator or slip ring.

- Use seating stones (pumice stones): At low or no load, apply seating stones to quickly adapt the brush face to the commutator/slip ring curvature. Always use “M” grade (Medium grain) stones for final finishing.

- For heavy adjustment: If a large amount of material must be removed, rough-grind with 60–80 grit sandpaper. Place the abrasive face upward between the brush and the commutator, moving it back and forth gently.

- Thorough cleaning: After seating, carefully clean the surface to remove all abrasive material and carbon dust.

3. Commutator and Slip Ring Surface Preparation

A properly prepared surface ensures stability and long brush life.

- Check roundness: Ensure the commutator/slip ring is not out-of-round beyond 3 mils (75 μm) and free from defects.

- Grinding or machining: If needed, machine or grind the surface using a proper tool support frame.

- Chamfer bar edges: Chamfer edges by 0.2–0.5 mm at 45° to prevent sharp edges from damaging brushes.

- Surface finish: Clean with “M” grade grinding stones (avoid abrasive cloth/paper). The surface must maintain a roughness of 1.3–2 µm Ra, which helps in forming a stable film for reliable brush operation.

4. Final Notes

Following these guidelines ensures reliable brush performance, reduces wear, and extends the lifespan of both brushes and commutators/slip rings. Proper installation and surface preparation not only improve efficiency but also minimize costly downtime due to electrical failures.