Introduction:

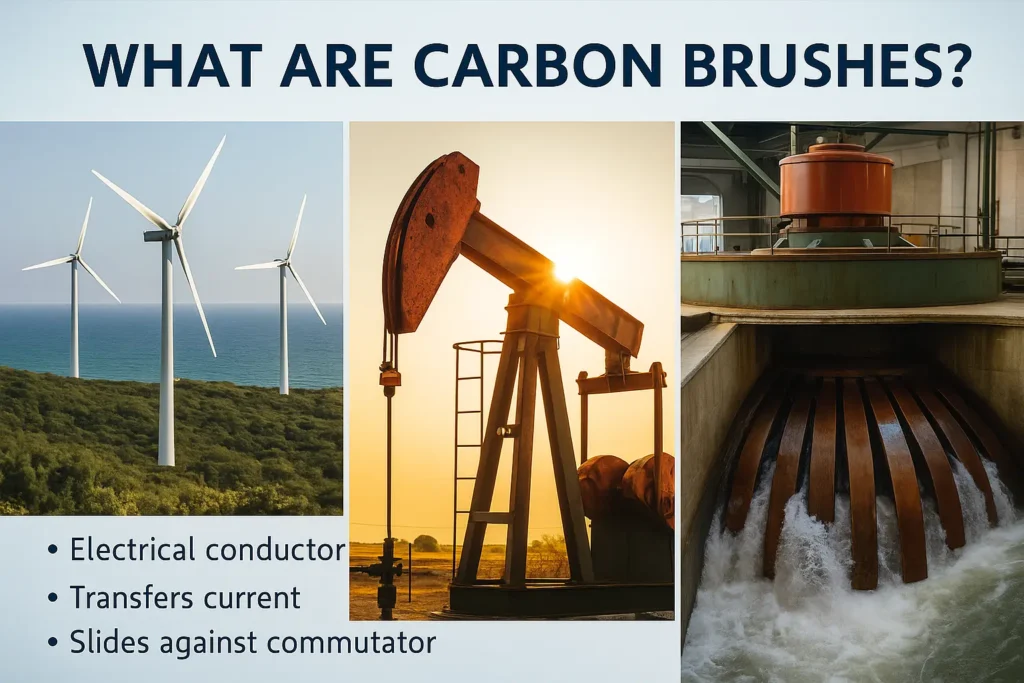

In the world of electric motors and generators, a small but essential component is the carbon brush. Often overlooked, these parts are crucial for the efficient operation of machinery across various industries—from energy generation to manufacturing and transportation. But what exactly are carbon brushes, and why are they so important? In this article, we’ll explore their function, materials, and applications in a simple, easy-to-understand way.

What Is a Carbon Brush?

A carbon brush is an electrical conductor that facilitates the transfer of current between the stationary and rotating parts of motors and generators. Made from materials like carbon or graphite, which are known for their excellent conductivity and durability, carbon brushes ensure a continuous flow of electricity while reducing wear on the commutator or slip ring.

Carbon brushes are typically mounted in a spring-loaded holder, pressing against the rotating part of the motor. This enables smooth power transmission, allowing the motor to work efficiently without excessive wear on the components.

How Do Carbon Brushes Work?

Carbon brushes work by maintaining a continuous electrical connection between the stationary and rotating parts of a motor or generator. As the motor turns, the brushes slide across the commutator or slip ring, transferring electrical current while minimizing friction. The carbon or graphite material helps reduce wear on both the brush and the commutator, improving the lifespan and efficiency of the motor.

Materials Used in Carbon Brushes

The materials used in carbon brushes have a significant impact on their performance. While traditional carbon brushes are made from carbon, many modern brushes incorporate other materials for enhanced performance:

- Carbon: The most common material, offering excellent conductivity and wear-resistance.

- Graphite: A preferred option for high-temperature environments due to its superior lubrication properties.

- Copper and Metal Composites: These materials are often added to improve electrical conductivity and heat resistance in high-performance applications.

- Resin-Bonded Brushes: These brushes are highly durable, making them ideal for heavy-duty industrial applications.

The choice of material depends on the specific needs of the motor, such as its speed, voltage, and operating temperature.

Key Applications of Carbon Brushes

Carbon brushes are used in a wide range of industries and applications, including:

- Energy Generation: Carbon brushes are essential in power plants, wind turbines, and other energy-generation systems where reliable motor performance is required.

- Industrial Manufacturing: In steel mills, mining operations, and cement plants, carbon brushes are used to ensure smooth operation of machinery and prevent downtime.

- Transportation: In electric vehicles and locomotives, carbon brushes are critical for motor operation and regenerative braking systems.

- Food Processing and Home Appliances: From refrigerators to mixers, carbon brushes ensure durability and performance in everyday appliances.

Why Choose High-Quality Carbon Brushes?

High-quality carbon brushes provide several key benefits for industries relying on electric motors:

- Customization: Carbon brushes are available in various sizes and materials to meet the specific requirements of different motor types and operating conditions.

- Durability: High-performance brushes are designed to withstand harsh conditions, ensuring extended operational life and minimizing downtime.

- Efficiency: Properly selected carbon brushes improve energy efficiency, reduce wear on motor components, and lower the cost of maintenance.

How to Choose the Right Carbon Brush for Your Application?

Selecting the right carbon brush is crucial for optimal motor performance. Factors to consider include:

- Motor Type: Whether you have a DC motor or AC motor, the carbon brush needs to be suitable for the specific type of motor.

- Operating Environment: High-speed or high-temperature applications may require brushes made of materials like graphite or copper composites to handle the demands.

- Power Requirements: The motor’s electrical load and operating conditions will determine the correct size and type of carbon brush needed.

Conclusion: The Essential Role of Carbon Brushes

Though small in size, carbon brushes play a significant role in the operation of electric motors and generators. Their ability to maintain an uninterrupted electrical connection while reducing friction is vital for industries such as energy generation, manufacturing, and transportation. By selecting the appropriate carbon brush material and design for your application, you can ensure optimal motor performance, increase efficiency, and extend the lifespan of your equipment.

Call to Action: Interested in learning more about how carbon brushes can enhance the performance of your equipment? Contact us today for more information or to explore our range of high-quality carbon brushes for industrial and commercial use!