Carbon Brush Data Sheet

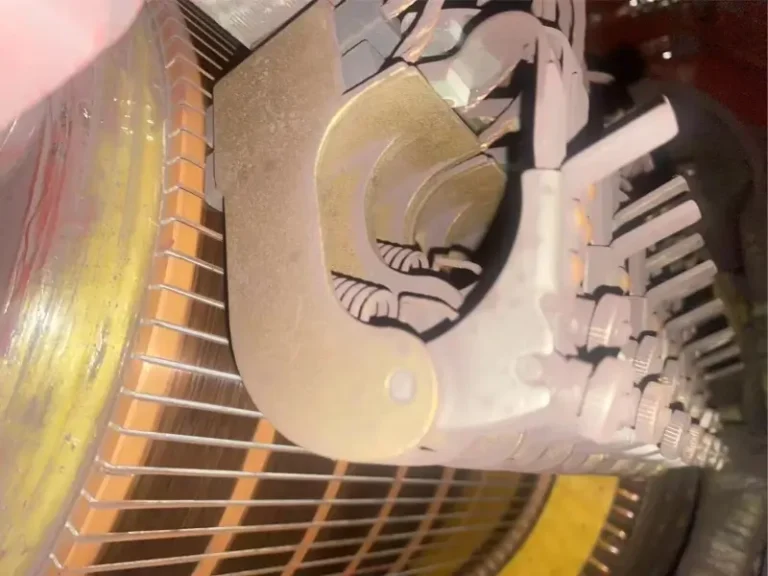

| Grade | D104 / J201 / J164 |

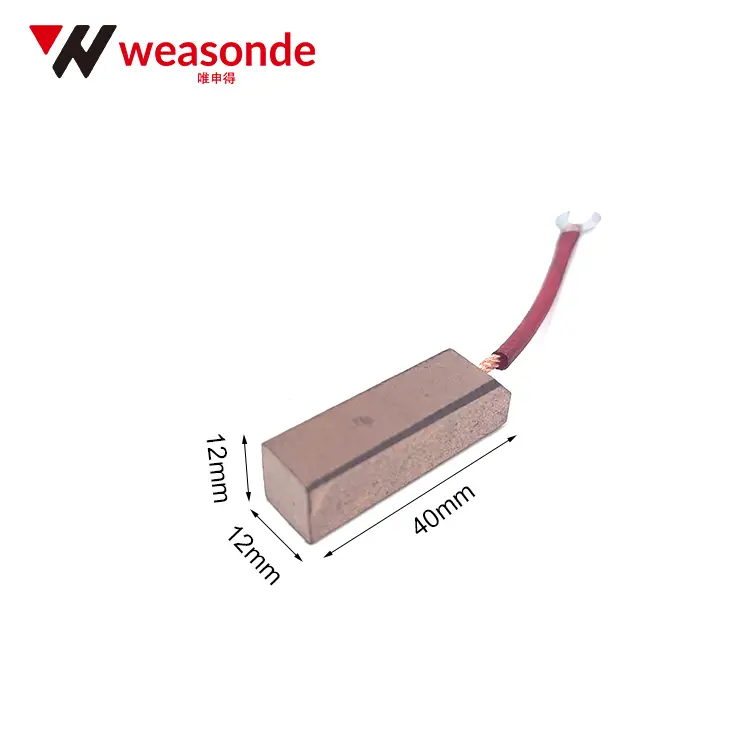

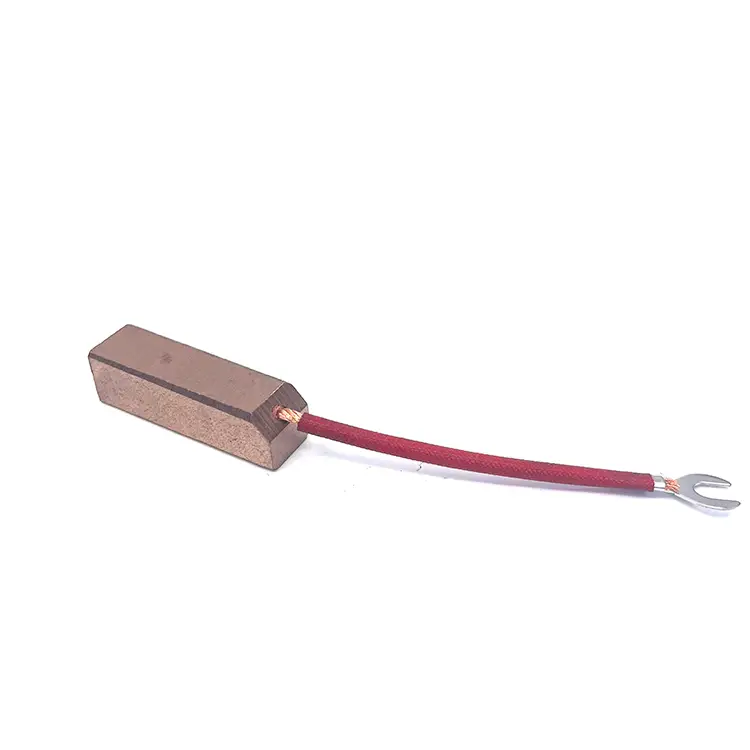

| Size | 12×12×40mm (Thickness×Width×Length) |

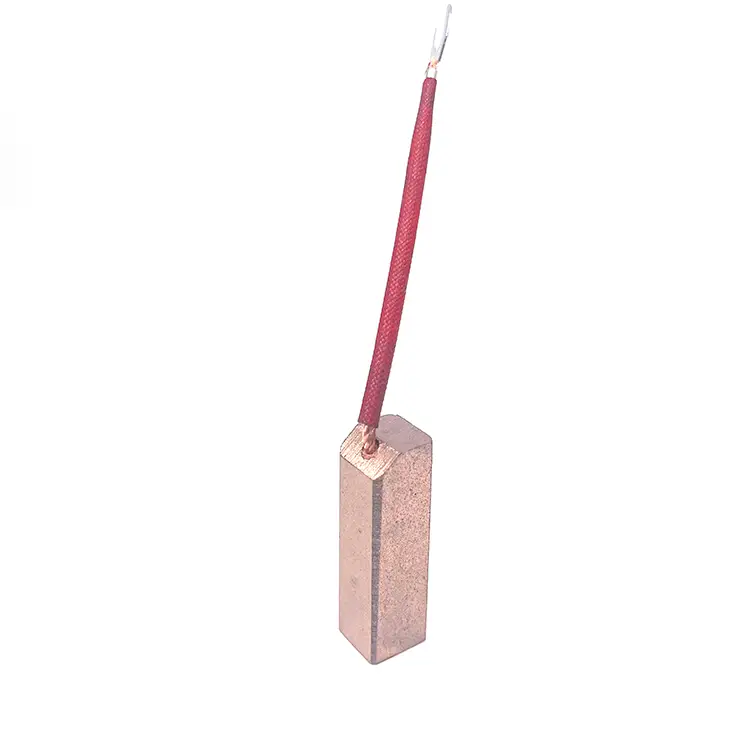

| Material | Carbon Graphite / 50% Copper / 85% Copper |

| Brand | Weasonde |

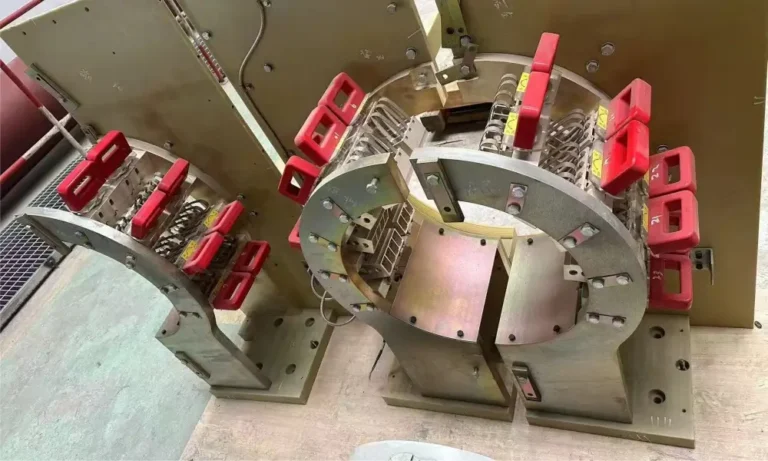

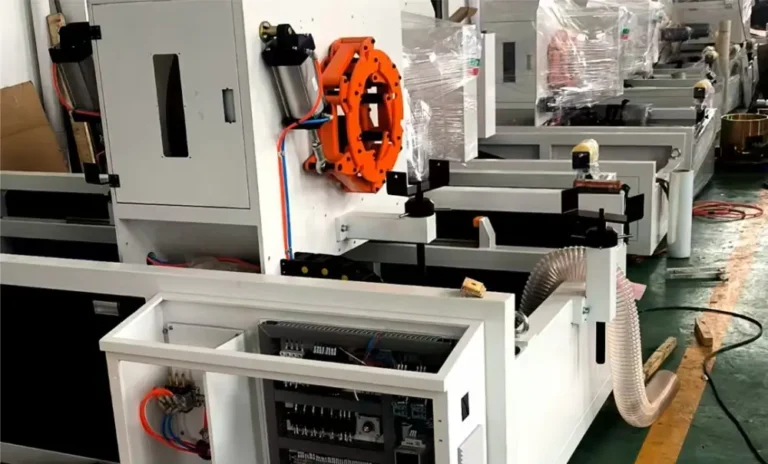

| Application | Diesel Generator, Indentation & Printing Machine |

| Certification | ISO9001:2008 |

| Company | Manufacturer |

| Warranty | 12 Months |

| Delivery Time | 5-15 Working Days |

Carbon Brush Material Comparison

- Graphite Carbon Brush

• Advantages: Stable conductivity, low friction, economical, suitable for long-term operation.

• Disadvantages: Lower current capacity, not ideal for heavy-duty equipment.

• Applications: Printers, light-duty generators, precision instruments.

- Semi-Copper Carbon Brush

• Advantages: Balanced conductivity and wear resistance, reliable performance, longer service life.

• Disadvantages: Higher friction than graphite, not suitable for very high-speed motors.

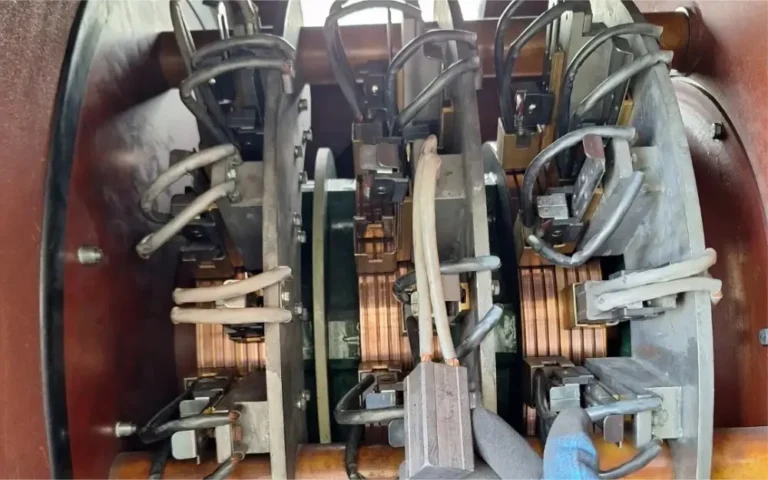

• Applications: Standard diesel generators, industrial machinery, general motors.

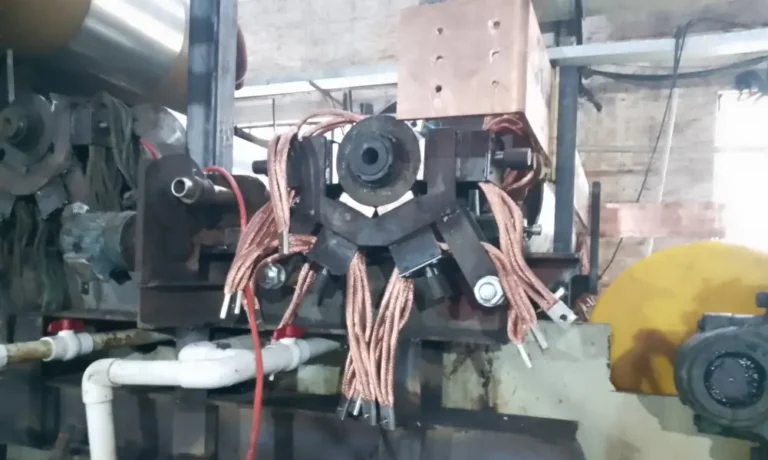

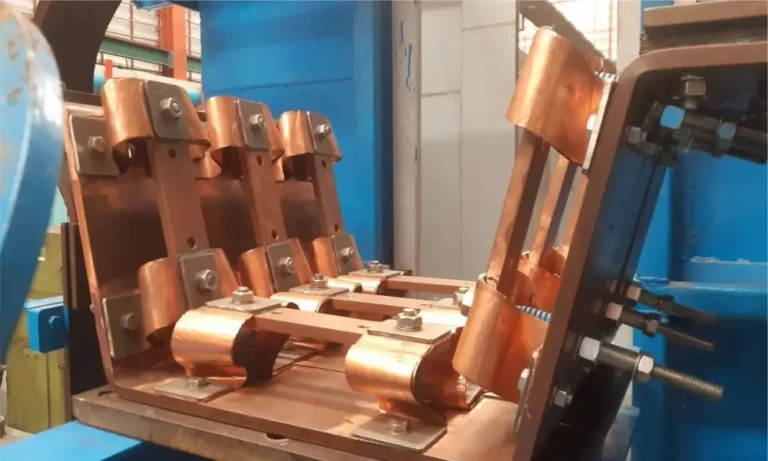

- High-Copper Carbon Brush

• Advantages: Excellent conductivity, strong current capacity, high durability under heavy loads.

• Disadvantages: Faster wear, may cause more wear on the commutator.

• Applications: Large diesel generators, heavy-duty motors, metallurgy and mining equipment.

🌟 Summary

• Graphite → Stable & light load

• Semi-Copper → Balanced & general use

• High-Copper → Strong current & heavy-duty